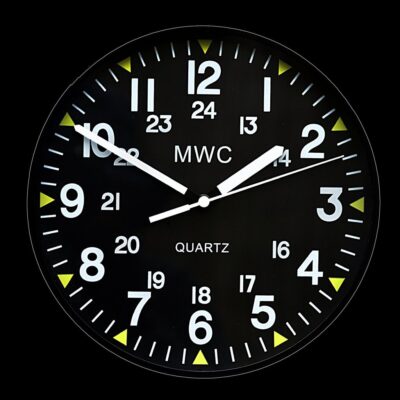

MWC 24 Jewel 300m Automatic Divers Watch with PVD Bracelet, Ceramic Bezel and Sapphire Crystal

£375.00

SKU Code: SUB/PVD/S/ABB

This watch is one of our current military specification divers watches in a covert black PVD finish, the watch has a ceramic bezel and scratch and shatter-resistant sapphire crystal with non-reflective coating, the watch is powered by an automatic (self-winding) 24 jewel model with a 41-hour power reserve, when all these attributes are combined they create a watch that is exceptional value for such a high specification timepiece.

The special covert matt black non-reflective PVD finish used for this watch is often specified in military contracts for many special forces units as well as by anti-terrorist units and for various covert operations. In the PVD process, the steel is not black all the way through because the colour is created by a special chemical PVD plating process which is vastly superior to the painted finish used on some lower quality watches which can easily fade or rub off. This PVD process means that the colour of the steel is altered at a molecular level, therefore it will not deteriorate even during heavy usage although it can be destroyed if the case is badly damaged by a piece of metal being gouged out or if the case is worn down by continuous heavy abrasion against rocks etc.

This watch uses the same 20mm lug sizeB as manyB other military divers watches giving access to a vast array of different straps and bracelets to suit your personal taste.

Dimensions and Specification:

- Water Resistance: 300m / 1000ft Water Resistant

- Crown: Screwdown locking

- Width Inc Crown: 45mm (Exc Crown 40mm)

- Thickness: 15mm

- Movement: 24 Jewel NH35A

- Crystal: Shatter and Scratch Resistant non-reflective sapphire*

- Crystal Diameter: 31mm

- Lug to Lug: 49mm

- Weight: 170g

- Illumination: Super Luminova

- Strap: 20mmB Black PVD Steel Bracelet

- 24 Month Warranty

* A lot of people ask us what are the benefits of sapphire crystal over a standard mineral crystal? The answer is that synthetic sapphire is by far the best material for watch crystals because it is very strong and also shatter and scratch-resistant, these characteristics make it very appealing to military and security personnel, police officers and people who lead active outdoor lifestyles, these groups account for over 70% of our customers. To get things into perspective we find that when clients have accidents with watches resulting in a cracked crystal over 90% usually watches with mineral glass crystals, even factoring in that we use hardened mineral crystals they still do not come close to sapphire for durability under adverse conditions. The reason that sapphire crystals are so strong is that after the sapphire glass is manufactured it is also heat-treated to remove its internal stressesb which can cause weaknessb it is then made into the watch crystals and two layers of anti-reflective coating are applied, interestingly sapphire crystal is now used on the latest iPhone. Of course, sapphire crystal comes at a price hence you find that it’s normally only fitted to higher-end watches.

B

Related products

Divers Watches

Chronographs